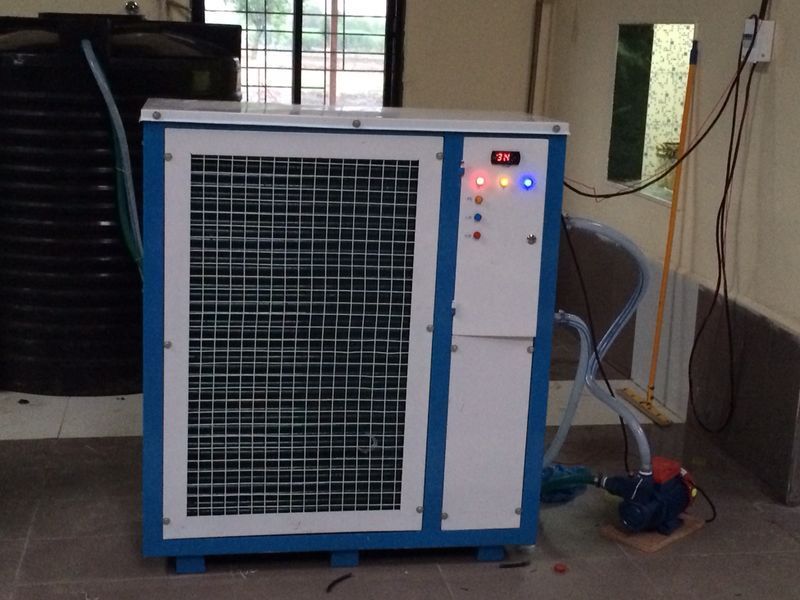

Industrial Water Chiller

Product Details:

- Usage Industrial

- Color White

- Product Type Water Chiller

- Material Steel

- Voltage 220 Volt (v)

- Click to View more

Industrial Water Chiller Price And Quantity

- 1 Piece

Industrial Water Chiller Product Specifications

- 220 Volt (v)

- Industrial

- Water Chiller

- Steel

- White

Industrial Water Chiller Trade Information

- 100 Piece Per Week

- 10 Days

- All India

Product Description

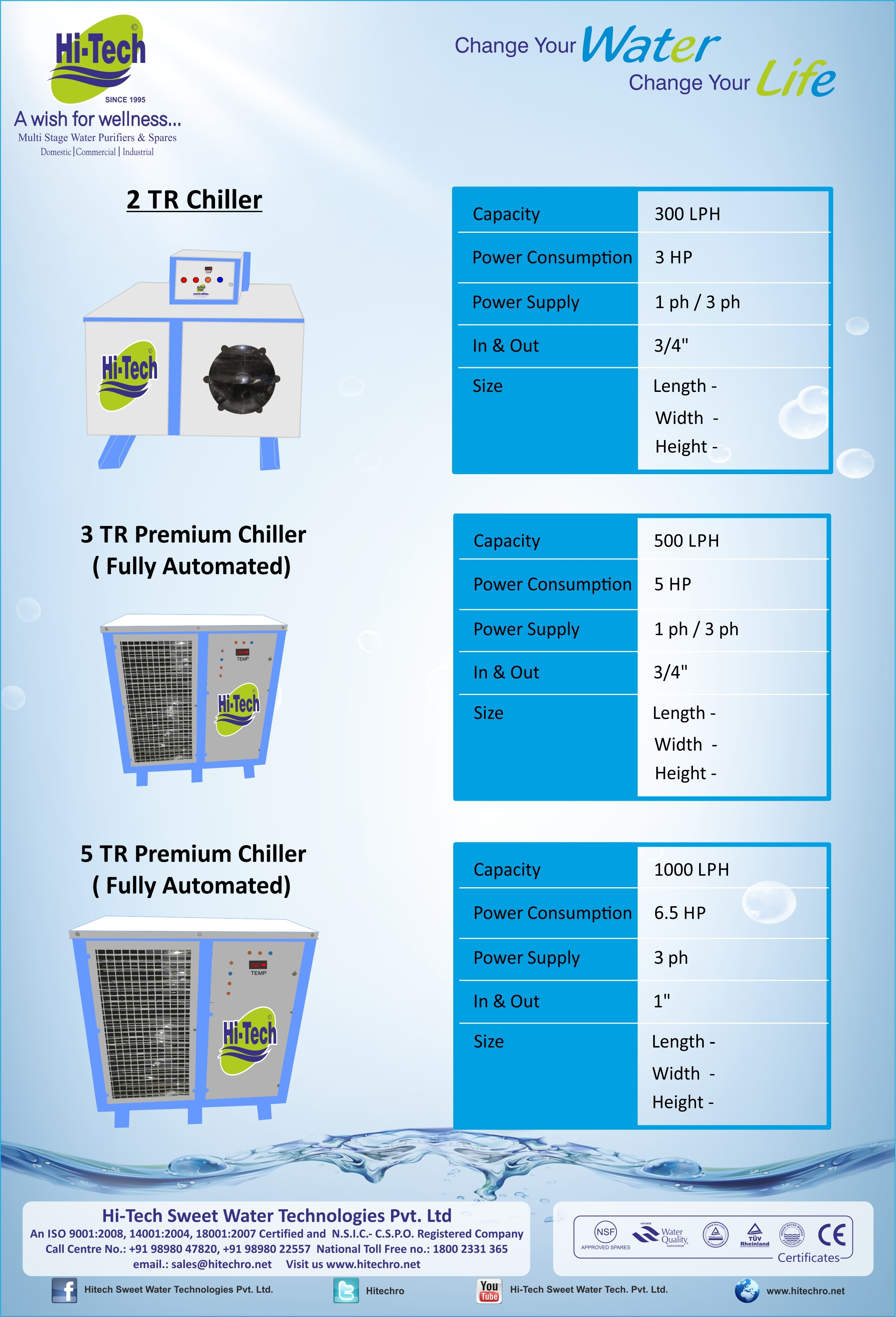

| SPECIFICATION OF 3 TR AIR COOLED CHILLER | | | | | |||

| | | | | | | ||

| SR. NO. | Technical Parameter | | Value | | |||

| | | | |||||

| {1} | ed | Skid Mounted Air Cooled Chiller | |||||

| | |||||||

| {2} | Ambient Temp. | 48 degree Celsius(Maximum) | |||||

| | |||||||

| {3} | Product Flow Rate | | 450 LPH | | |||

| {4} | Max. Relative Humidity | | 100% | | | ||

| {5} | Compressor | | Semi Sealed | | |||

| | | | |||||

| {6} | Refrigerant Capacity | | Total-3 Tr | | |||

| | | | |||||

| {7} | Product inlet | | 30 Degree Celcius | ||||

| {8} | Chilled Product outlet | | 20 Degree Celsius | ||||

| | | ||||||

| | | | | | | ||

| {9} | Refrigerant gas | | R-22 | | |||

| | | | |||||

| | | | | | | ||

| {10} | Power supply 3 phase 50 HZ AC | | 415 V | | |||

| | | | |||||

| | | | | | | ||

| {11} | Control Supply AC Single phase | | 230 V | | |||

| | | | |||||

| {12} | Motor Power | | 3.4 KW | | |||

| | | | |||||

| {13} | Noise Level | Less than 80 db at 1 meter Distance | |||||

| | |||||||

|

| | S.no. | Product | Features | |||

|

| | | |||||

|

| | | Compressor with built in Motor | Semi Sealed Compressor | |||

|

| | | | ||||

|

| | | | | |||

|

| | {1} | | Shut off valve at inlet | |||

|

| | Compressor Accessories | | ||||

|

| | Shut off valve at outlet | |||||

|

| | | |||||

|

| | | | | |||

|

| | | | Non-return valve at outlet | |||

|

| | | | High pressure cutout set with | |||

|

| | | | display. | |||

|

| | | | | |||

|

| | | | Low pressure cutout set with | |||

|

| | | | display. | |||

|

| | | | Chilled water flow failure trip | |||

|

| | {2} | Safety Interlocks | Digital Temperature contoller | |||

|

| | | | ||||

|

| | | | Compressor & Pump overload Trip | |||

|

| | | | Under Voltage/Over voltage /single | |||

|

| | | | phasing preventor/Reverse phasing | |||

|

| | | | preventor | |||

|

| | | | | |||

|

| | {3} | Control Panel | Fully Automatic control Panel | |||

|

| | | |||||

|

| | | | | |||

|

| | | | Design:-As per TEMA/ASME Section | |||

|

| | {4} | Condenser (Air Cooled) | VIII,Div.1 | |||

|

| | | |||||

|

| | | | Fin & Tube Type :- Copper Tube and | |||

|

| | | | Alluminium Fin | |||

|

| | | | | |||

|

| | {5} | Chiller | Imported Brazed type Plate heat | |||

|

| | Exchanger | |||||

|

| | | | ||||

|

| | {6} | Capicity Control | 1 system 100% | |||

|

| | | | | |||

|

| | {7} | Expansion Valves | Sporlan- USA make for minimum | |||

|

| | | |||||

|

| | | superheart for Evaporator. | ||||

|

| |

|

| ||||

|

| | | | Inerconnecting refrigerant piping | |||

|

| | {8} | Gas piping | Copper(based on the compact layout.) | |||

|

| | | | Structural standfor compressor, | |||

|

| | | | condenser ,liquid receiver, chiller. | |||

|

| | | | | |||

|

| | | | Assembly & installation of the | |||

|

| | | | complete chilling plant | |||

|

| | | | | |||

|

| | | | Pressure test with nitrogen for | |||

|

| | | | leakage, vacuum test & charging of gas | |||

|

| | {9} | Installation &Commissioning(Will Be charged Extra) | into the chiller. | |||

|

| | | | ||||

|

| | | | | |||

|

| | | | Instrument cabling up to the control | |||

|

| | | | panel | |||

|

| | | | Commissioning of the chiller. | |||

|

| |

|

|

| |||

|

| | | | All civil work such as foundation for | |||

|

| | | | all the equipment, housing for | |||

|

| | | | equipment, cutting away and making | |||

|

| | | | good walls, floors, slabs etc. | |||

|

| | {10} | Exclusions | | |||

|

| | | | Power cabling & earthling | |||

|

| | | | | |||

|

| | | | Insulation of process water piping. | |||

|

| | | | | |||

| | | | | | | | |

| S.No | Item | Make/Manufacturer |

| | | |

| | | |

| {1} | Compressor | Kirloskar |

| | | |

| {2} | Condenser | SBC Make |

| | | |

| {3} | Evaporator | Imported Brazed PHE |

| | | |

| {4} | Base Frame | SBC make |

| | | |

| {5} | Expansion value | Sporlan |

| | | |

| {6} | LP/HP switch | Danfoss |

| | | |

| {7} | Oil level Switch | Danfoss |

| | | |

| {8} | Control panel | SBC make(Fully Automatic) |

| | | |

| {9} | Electricals | Siemens |

|

|

|

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'RO Water Cooler' category

|

HI-TECH ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |